A Complete Guide on PCB Drilling Process

A Complete Guide on PCB Drilling Process

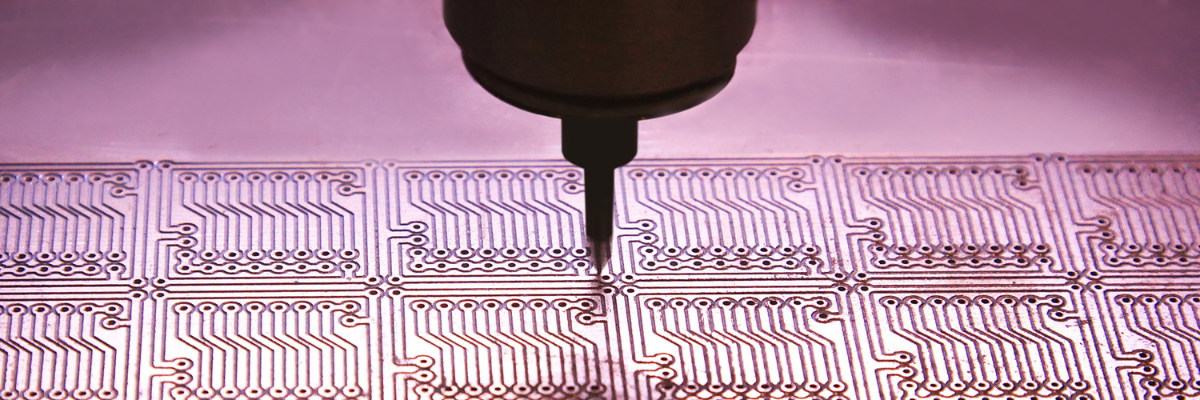

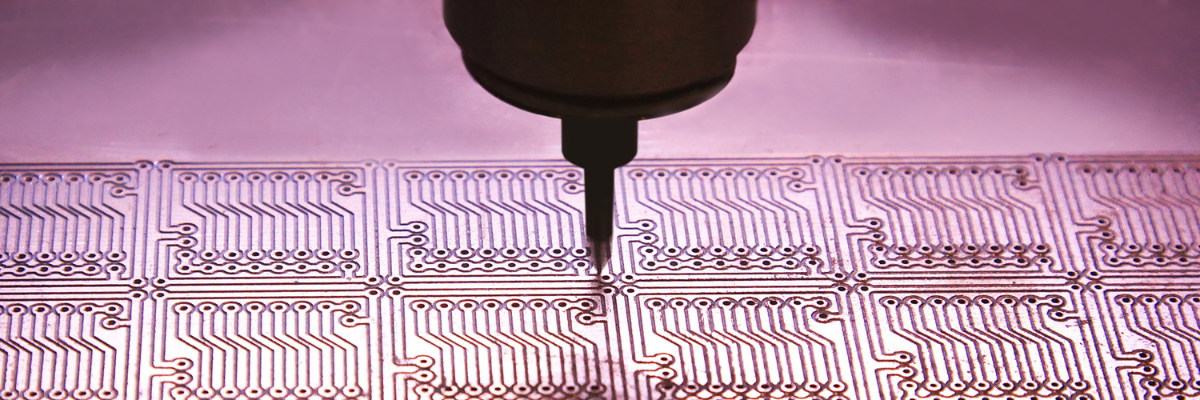

Over the last few years, PCBs have played a huge role in the way various industries function. They have helped increase speed, automation, and time to market for many products. Hence, the demand for PCB manufacturing and assembling is huge across industries. This small board carries several components, wires, solder joints, and more. To mount components on the board, holes need to be drilled using specific methods and in the right places. These boards have electrical conductivity between the wirings on every layer controlled by vias. This is where drilling plays a key role in PCB design and manufacturing, creating a secure base of plating on hole walls. Simply put, PCB drilling is the process of creating holes in circuit boards. This is performed to facilitate placement and interconnection between electrical components on different layers. Are you intrigued to know more about PCB drilling? Read this post till the end.

Classification of Drill Holes in the PCB

Drill holes are differentiated based on the current carrying tendency of the circuit boards. However, this classification does not cover the significance of drill holes in PCB design and manufacturing. Thus, the best way to classify drill holes is based on their uses in the circuit board. Broadly, drill holes are classified into two types – plated through holes (PTHs) and non-plated through-holes (NPTHs). These two terms are described below:

-

Plated Through Holes: They are signal carrying conductive vias that interconnect different layers in the circuit boards. Each type mentioned below has its own design rules and strengths.

-

Buried Vias: Also called hidden vias, these are located in the inner area of the circuit board. Thus, there is no path toward the outer layers. They are drilled mechanically.

-

Blind Vias: They can be mechanically drilled from either top or bottom. These vias establish a connection between the internal layer and the surface of the stack-up. Blind vias are only applied to targeted layers.

-

Micro Vias: As the name suggests, they are small compared to other vias. They may be buried or blind.

-

Thermal Vias: They don’t have any specific structure. They are located under a surface-mounted heat source in PCB for heat removal.

-

Non-plated Through Holes: They are non-conductive and hold electrical components in the required position during the circuit board assembly process.

-

Fasteners: They are mainly used for mechanical adhesion. They ensure that the additional support required for any installed component is neatly installed.

-

Mounting Holes: These are mainly intended for fasteners in component installation where vertical clearance is not essential.

-

Countersink Holes: Also called conical holes, they are used for PCB assembly wherein the bolt head is lowered below the surface.

Pointers to Be Considered in the PCB Drilling Process

After understanding the basics and classification of the PCB drilling process, it is important to keep a few things in mind during the drilling process. Here are two important aspects regarding the same:

-

Aspect Ratio: It is defined as the ability to deposit copper inside vias. This becomes challenging when the depth of the vias increases, and the diameter decreases. This is where a copper plating bath makes a significant difference. Once this value is known, molten copper can easily gush into the small holes.

-

Drill to Copper Clearance: It defines the distance between a hole and the nearest copper feature. The nearest copper feature can be any active copper region or a copper trace.

Proven PCB Drilling Tips and Tricks for Designers

PCB drilling demands a high level of precision and accuracy. The following proven tips will make the process easy and foolproof.

-

Before starting the actual process, it is important to drill a pilot hole. This will not allow the drill from slipping into other electrical components.

-

It is essential to use the right size of the drill bit to avoid circuit board damage.

-

Operate the drill bit with the right power and speed to go through the material.

-

A drill press is the most preferred equipment for accurate drilling and efficiently make the right sized holes.

-

Apply solder to the newly drilled holes and use a soldering iron to melt them. This securely attaches the solder around the holes.

The PCB drilling process is intricate and demands a high level of expertise and experience to prevent board damage and subsequent losses. This is because a small error can lead to significant damage. Thus, it is important to get this part of PCB manufacturing right. If in doubt, it is recommended to employ an industry-leading, reliable PCB manufacturer and assembler for the best possible solution. Twisted Traces stands tall among its other competitors. With vast years of market presence and a highly skilled workforce, the company offers a wide range of PCB capabilities to fulfill your application requirements.