How Pin Plating Materials Ensure Reliable PCB Connectors?

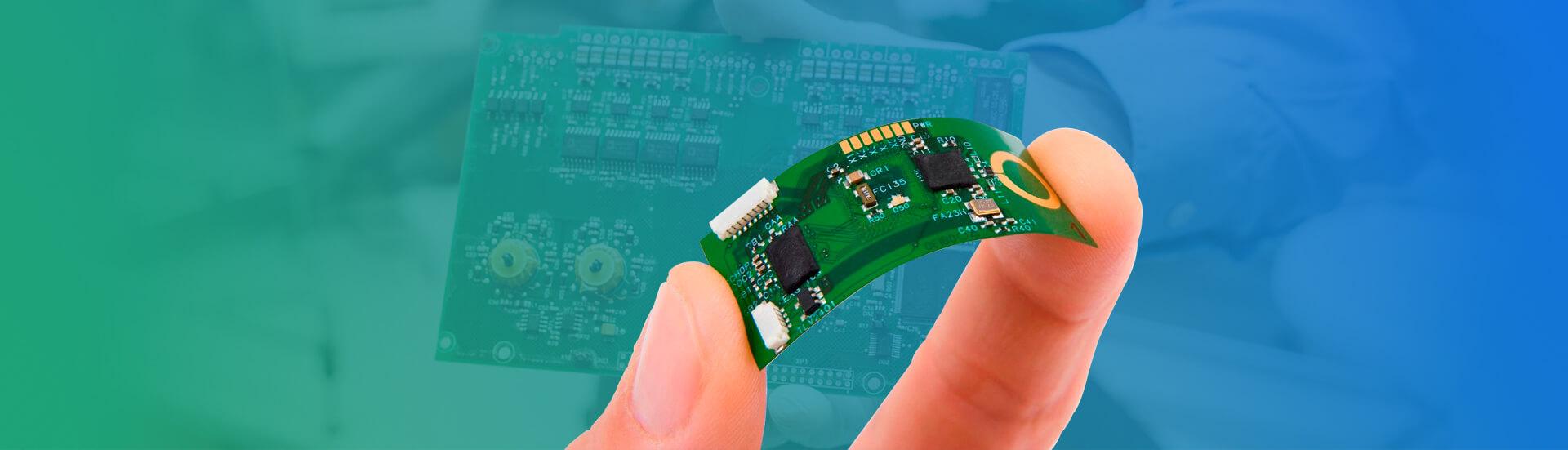

The reliability and performance of every PCB component are crucial to the functionality of electronic devices. Among these, electrical connectors are essential as they form the critical interfaces between various electronic components. The quality of these connections directly impacts individual devices and the overall system.