A Comprehensive Guide on PCB Recycling Process

A Comprehensive Guide on PCB Recycling Process

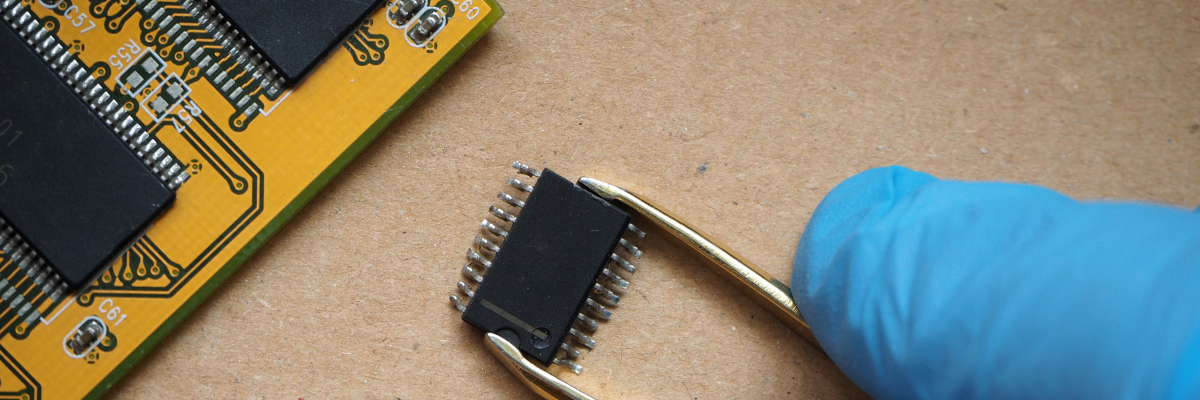

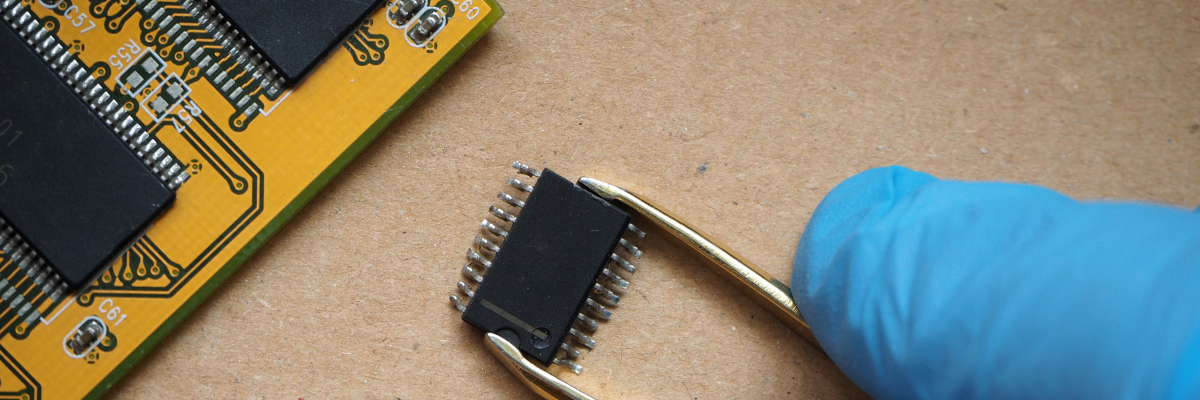

Printed Circuit Boards (PCBs) are integral to most electronic devices today. From smartphones to household appliances, these crucial components drive the performance and efficiency of devices. As technology evolves at an unprecedented pace, old electronics are discarded more frequently, leading to a surge in e-waste. This strains landfills and dissipates valuable resources. PCB recycling is a game-changer, turning electronic waste into a sustainable asset. But what exactly happens during the PCB recycling, and how can these boards be made more recyclable? Read this post to understand the essential steps of PCB recycling and discover strategies to enhance their recyclability.

Recycling PCBs – Know-How It Is Done

Recycling PCBs seems a straightforward process; however, it involves several steps and the expertise of waste management professionals. Here is a brief overview of these processes.

-

Physical Recovery: This method involves mechanically breaking down PCBs into smaller pieces, making sorting and material separation easier. The process begins by shredding the PCBs, followed by techniques, such as air classification or magnetic separation, to extract metals from other components. This method is efficient and reduces the volume of waste, but it might not recover all types of metals effectively.

-

Thermal Recovery: This process involves heating the shredded PCB material to extremely high temperatures. The heat melts metals, separating them from non-metallic components. These molten metals are then collected and refined. This method is highly effective for extracting metals like gold and silver but requires careful control to prevent the release of toxic fumes.

-

Chemical recovery: As the name implies, specialized chemical solutions are used to extract valuable metals. Acids or other chemicals are used to dissolve the metal content from the PCB material. Once done, the metals are separated from the remaining materials. This technique helps recover rare metals and can be tailored to target specific elements.

-

Pyrometallurgy: This recycling method harnesses the power of fire to recover metals. The PCBs are subjected to high temperatures, enabling the separation of metals based on their different melting points. The molten metals are then collected and purified. Pyrometallurgy is highly effective for extracting valuable metals but requires substantial energy and careful management of emissions.

-

Hydrometallurgy: This process uses aqueous solutions to dissolve and separate metals from PCBs. Treating the shredded PCB material with specific chemicals selectively dissolves the metals. It's a versatile process that can recover a range of metals and is often used with other methods for optimal results.

-

Electrochemical Process: By applying an electric current to a solution containing dissolved metals, this method deposits the metals onto electrodes, making them easy to collect and refine. It's an efficient way to recover metals with high purity and is often used with other recycling techniques.

Making PCBs More Recyclable

It is essential to focus on practical strategies to make PCBs more recyclable. The following approach enhances PCB recyclability:

-

Use Environmentally Friendly Materials: It's essential to use eco-friendly materials to enhance PCB recyclability. Replace hazardous substances, such as lead and brominated flame retardants, with lead-free solders and halogen-free laminates. Opting for biodegradable or bio-based substrates instead of traditional fiberglass and epoxy can simplify the process. Incorporating metals that are easy to recover benefits in many ways. Copper and gold are two popular choices

-

Improve Manufacturing Processes: Improving PCB manufacturing processes can facilitate better recycling outcomes. Opt for mechanical fasteners, which are easier to remove and don't contaminate materials. Additionally, optimizing the manufacturing process through precise cutting and efficient raw material use ensures more material is available for recycling and reduces overall waste.

-

Design for Disassembly: Simple PCB layer structure reduces the complexity of separating components. Modular designs allow PCBs to be taken apart into short and manageable sections. This makes sorting and recycling easy. Clear labeling of materials further aids recyclers in identifying and handling different components efficiently.

-

Reduce Material Complexity: This can significantly improve the PCB recycling process. Avoid using multiple tightly bonded materials that are difficult to separate during PCB recycling. Instead, prefer PCB design with uniform materials, such as a single type of plastic, to simplify the recycling process and enhance efficiency. This approach reduces the challenges associated with sorting and processing.

Recycling circuit boards is crucial for managing electronic waste and conserving valuable resources. By understanding the recycling process and taking proactive steps to enhance recyclability, both OEMs and consumers can play a vital role in promoting a sustainable future. If you have any questions or need expert guidance, consulting a reliable partner in the industry can be immensely beneficial. With extensive experience and expertise, Twisted Traces, specializes in PCB manufacturing and assembly services. The company emphasizes on eco-friendly strategies, including sustainable materials and efficient manufacturing processes. These initiatives make the PCB recycling process more streamlined and effective. For more information, reach out to their expert team.

.png)

.png)