Challenges and Solutions in PCB Supply Chain Management

Challenges and Solutions in PCB Supply Chain Management

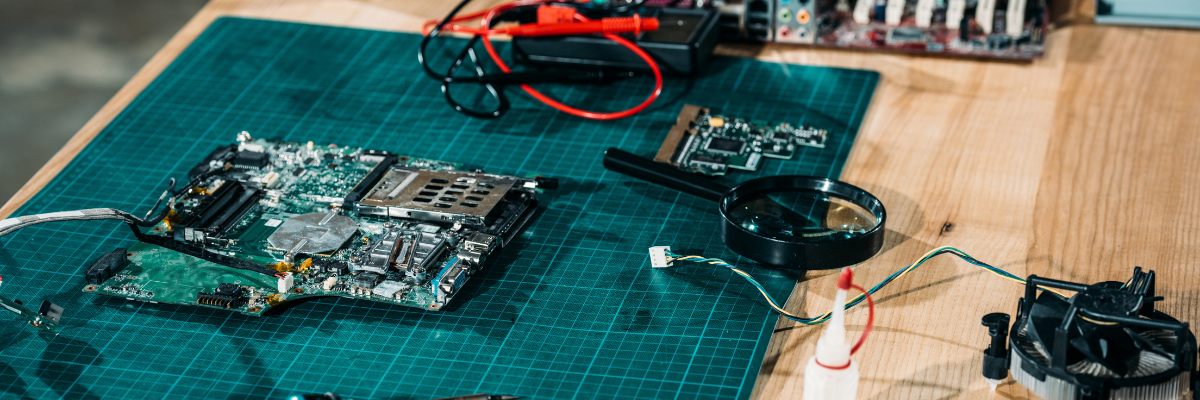

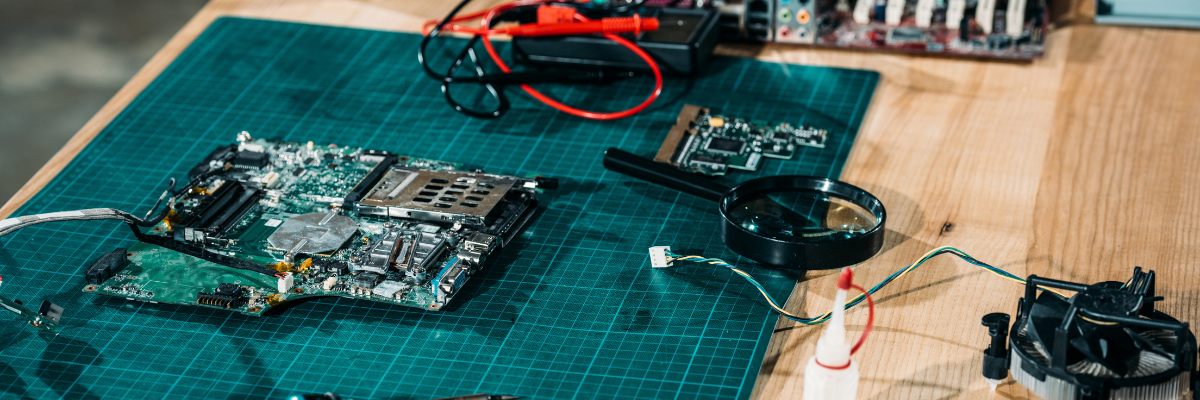

PCBs are essential components in the electronic industry that enable electricity flow between connecting components. They play a vital role in ensuring the efficient assembly and reliable performance of many devices ranging from smartphones to industrial machinery. PCBs are extensively used in various industrial devices and equipment. However, these industries are affected by the global supply chain issues in the PCB industry. This post discusses significant supply chain management challenges and explores the solutions that can handle these concerns.

Challenges in the Global Supply Chain Impacting PCB Manufacturing:

The following are several challenges in the global supply chain that are impacting PCB manufacturing in the US and worldwide.

-

Raw Material Shortages: A printed circuit board assembly relies on raw materials, such as substrates, copper, laminates, and chemicals. Shortages of these materials can affect the supply chain.

-

Logistic Bottlenecks: The pandemic has unveiled the frailties and fragilities in global logistics, highlighting issues such as container shortages and port congestion. These problems have led to transportation delays and surged shipping costs, impacting the timely procurement of PCB materials.

-

Geopolitical Tensions: The supply chain may be disrupted by trade policies, geopolitical tensions, and tariffs. For instance, the tensions between countries that import or export raw materials needed for PCB production can affect the overall timelines and costs.

-

Reduced Supply Chain Visibility: A PCB supply chain may feature various layers of subcontractors and suppliers. This would reduce the supply chain visibility and add to the complexity.

-

Quality Standards and Compliance: Maintaining compliance with industry standards is important. Differences in quality control across industries and regions can lead to increased rejection rates.

Strategic Solutions to Overcome PCB Supply Chain Hurdles:

To overcome the challenges above, manufacturers need to implement various strategic solutions that aim to improve resilience in supply chain management. Take a closer look at some of the solutions below:

-

Plan Ahead: To anticipate and mitigate the potential risks, disruptions and any uncertainties, you must develop comprehensive supply chain strategies and contingency plans. It would help minimize the impact of disruptions and ensure business continuity. This will also help organizations to optimize inventory levels and allocate resources more efficiently.

-

Choose Common Board Materials: To avoid any kind of delays and streamline procurement, you must choose standard materials that are widely used and align with your specifications conveniently. This will also streamline your inventory complexity and improve your economics of scale.

-

Diversify Supplier Sources: You need to expand the supplier base to enhance your relationships with multiple suppliers who can provide you with the required materials and critical components that are needed for production. Dependence on a single supplier only makes you more susceptible to risks, including supply chain disruptions, quality problems, and production delays. By doing this, you can lessen the effects of any one supplier breakdown or failure. Relying on multiple sources also proves to be a great help in unexpected events like natural disasters, geopolitical tensions, or supplier bankruptcies.

-

Prioritize Process Optimization: You can embrace lean manufacturing. The goal of lean manufacturing is to find and eliminate waste in any form, including errors, excess inventory, waiting periods, overproduction, needless movement, and unused talent. You can optimize resource usage and boost productivity by identifying inefficiencies and putting measures in place to reduce or eliminate waste through a thorough analysis of every step of the manufacturing process. Organizations can also adapt to changing market conditions, improve supply chain resilience, and maintain a competitive edge in today's dynamic business environment.

-

Partner with an Experienced PCB Fabrication and Assembly Service: Partnering with experienced PCB assembly services will help you overcome the challenges of the PCB supply chain. These assembly services usually partner with suppliers to source their components. They also maintain comprehensive inventory management systems, which ensure a consistent supply of high-quality components despite the above-discussed supply chain issues.

If you have been looking for experienced PCB assembly services for your next project, you can consider Twisted Traces. With 30+ years of fabrication and assembly experience to its credit, the company has helped several clients navigate the supply chain and manufacturing challenges all these years. Contact the team at Twisted Traces today to discuss your PCB assembly and fabrication requirements.