Factors to Consider Before Choosing A Quick Turn PCB Assembly Manufacturer Discussed

Factors to Consider Before Choosing A Quick Turn PCB Assembly Manufacturer Discussed

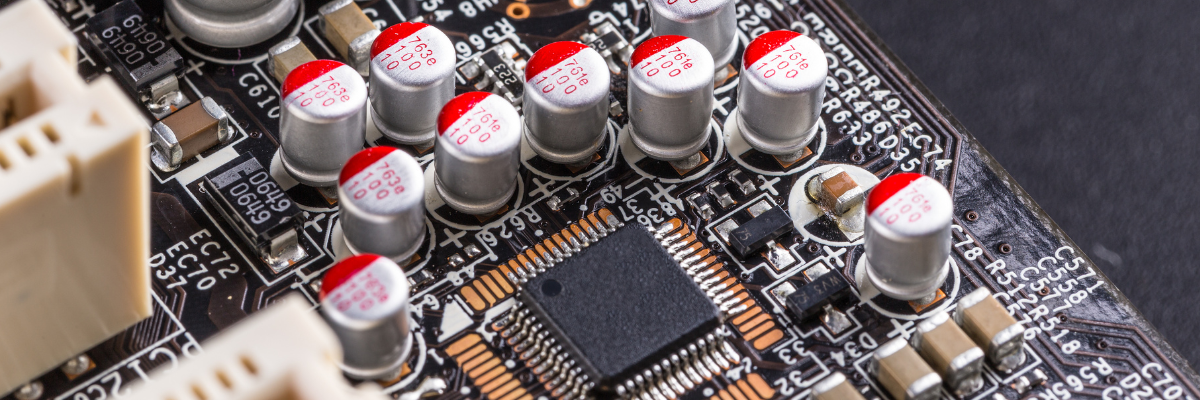

Printed circuit boards (PCBs) are essential components of electronic devices, and hence researchers, as well as PCB manufacturers, have strived to improve their design and manufacturing capabilities over the years. One of the most significant PCB capabilities - quick-turn PCBs is one such development implemented by PCB manufacturers and assembly service providers. This is driven by the high demand for PCBs across industries, considering the increasing level of digitization and automation of products and processes as well as machinery and equipment. Quick-turn PCBs imply fast prototyping and production of PCBs, which may be as quick as 24 hours, depending on the requirement and complexity. Quick turn PCBs are designed and manufactured with a shorter turnaround time than traditional ones. These PCBs are perfect for businesses that require quick production, assembling, and testing of a PCB assembly. Quick turn capabilities are also ideal for businesses when making design changes, developing prototypes, or new versions. Are you intrigued to know more about PCB capabilities -– quick turn PCB?

Applications of Quick-turn PCBs

When we speak about quick-turn PCBs and fast turnaround times, it is imminent that the basic and design part must be almost ready, especially for new productions. Quick turn PCBs are ideal for a wide range of applications that require fast and efficient prototyping or production of electronic devices. Here are some of the common applications of quick turn PCBs:

-

PCB prototyping: Quick turn PCBs are popularly used for prototyping and testing new designs. Manufacturers and assemblers offering these services have a set of packages ready so that the clients can select the right one and get it customized quickly. They allow engineers and designers to quickly produce a prototype PCB to test and refine a new product before committing to a large production run.

-

Small volume production: If a PCB fails after the complete production, designing a new PCB can be very costly, leading to downtimes. Quick turn PCB allows businesses to quickly produce a small batch of electronic devices to test the market before starting large volume productions.

-

Custom PCB designs: Quick turn PCBs are perfect for businesses that require custom-designed PCBs. They allow for quick and easy modifications to the design without taking much time.

-

Mission critical applications: Medical devices require complex printed circuit boards, and their prototyping is time-consuming. The same applies to sectors such as aerospace, defense, and automotive, which may require quick-turn prototypes to be sure of the design in the final product. PCB capabilities - quick-turn PCBs allow for the fast and efficient prototyping and production of these devices and equipment.

Important Factors When Choosing a Quick Turn PCB Assembly Service Provider

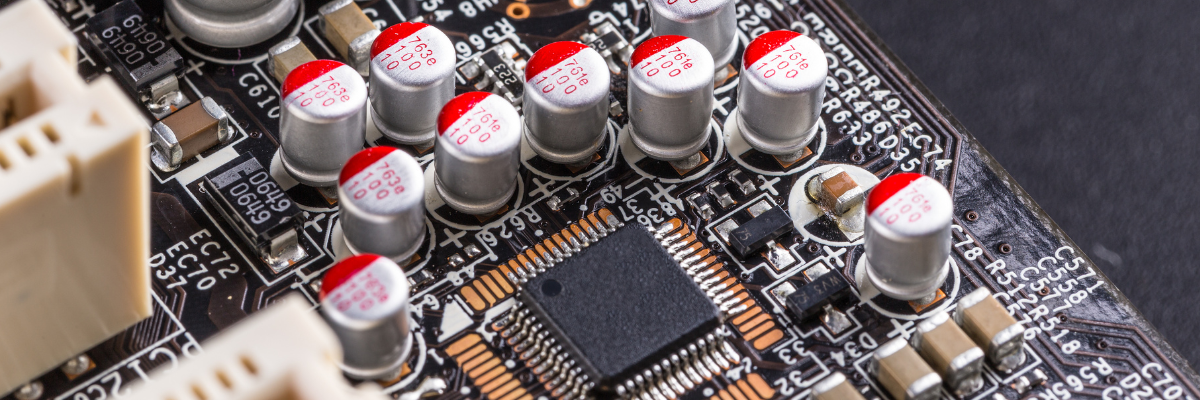

Choosing the right quick turn PCB manufacturer and assembly service provider is crucial for ensuring that your electronic device is of the highest quality, meets the application requirement, and is delivered on time. Here are some factors to consider when selecting a quick turn PCB assembly manufacturer:

-

Experience of the Manufacturer: Always look for a manufacturer with extensive experience in PCB assembly services. They must have a proven track record of producing high-quality PCBs with fast turnaround times as well as custom options.

-

Quality of the Products: This is one of the most important factors to consider before partnering with a quick-turn PCB manufacturer. Consider a manufacturer who has strict quality control measures to meet your industry standards.

-

Turnaround Time: The main benefit of quick turn PCB assembly is the speed at which it can be completed. Therefore, partner with a manufacturer that can guarantee fast delivery times without compromising on quality.

-

Use of Latest Technology: The manufacturer must use the latest technology and equipment to manufacture quick-turn PCBs. In addition, they should also have skilled technicians, designers, and engineers who can inspect and test the products before delivery for reliable service.

-

Customization Flexibility: The manufacturer should be flexible enough to accommodate any changes or modifications to your design. They must offer custom options from a range of product packages available.

Now, as you are familiar with quick-turn PCB applications, you may want to consider the factors mentioned above before partnering with a PCB manufacturer. Although there are various leading PCB manufacturers, Twisted Traces stands tall among all and meets all the standards and requirements in terms of speed, quality, and customization. Twisted Traces is the leading player in printed circuit board manufacturing and assembling. In addition, they offer high-quality and reliable quick-turn PCB services you can rely on. Get in touch with the team at Twisted Traces today for further details.