Key Differences between PCB Prototyping and Full Spec Production Explained

Key Differences between PCB Prototyping and Full Spec Production Explained

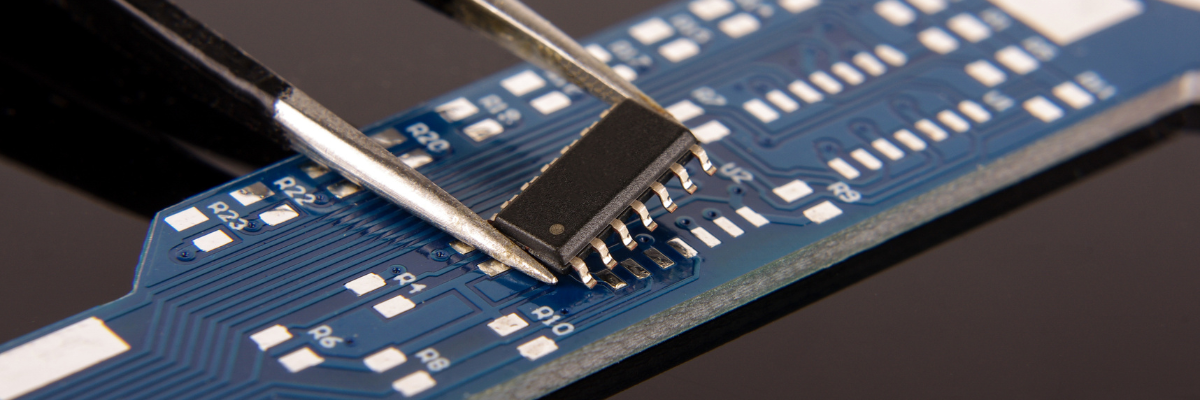

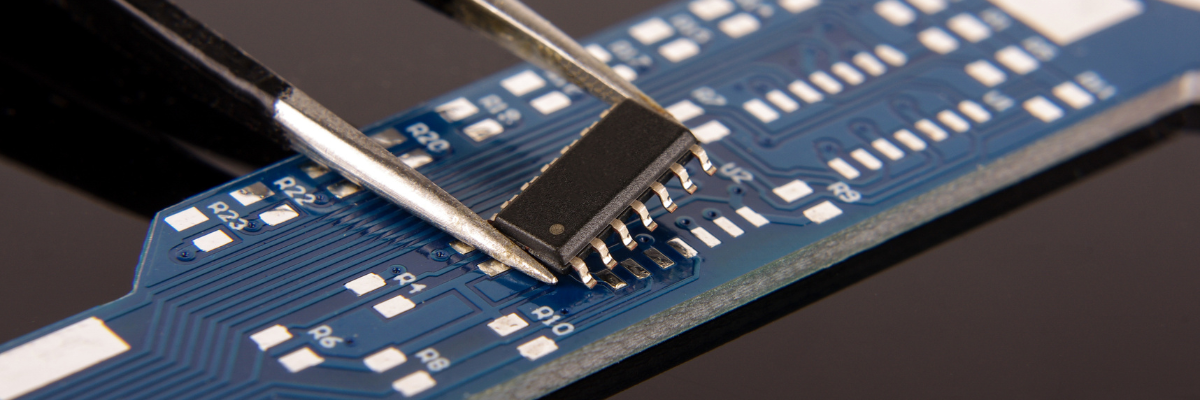

When it comes to the production of printed circuit boards, there are two main stages: prototyping and full spec production. While these terms may sound straightforward, understanding the differences between PCB prototyping and full spec production is highly significant for those involved in the electronics industry. This post aims to give you an insight into the major differences between the two processes, which in turn help you to make an informed decision.

PCB Prototyping and Full Spec Production: Major Differences.

While both PCB prototyping and full spec production involve the fabrication of PCBs, there are significant differences between the two. A few of them include:

-

Purpose: PCB prototyping involves the development of the functional prototype of a PCB design. This is done to test the design's functionality, performance, and compatibility with other components. Full spec production, on the other hand, involves the mass production of PCBs for commercial applications. In other words, the focus of full spec production is to making large quantities of consistent, high-quality PCBs that meet specific industry standards.

-

Quantity: Full spec production, involves the mass production of PCBs for commercial applications. In other words, the focus of full spec production is to make large quantities of consistent, high-quality PCBs that meet specific industry standards. PCB prototyping, on the other hand, involves the development of the functional prototype of a PCB design. This is done to test the design's functionality, performance, and compatibility with other components.

-

Lead Times: When it comes to PCB prototyping, the process is typically faster compared to full spec production. This is primarily because prototyping involves small quantities, allowing for shorter turnaround times. The emphasis lies on rapid iterations and design refinements. In contrast, full spec production demands longer lead times due to its larger scale, meticulous planning and coordination with suppliers.

-

Cost: The cost of PCB prototyping is typically higher on a per-unit basis compared to full spec production due to the smaller quantities involved. This is because prototyping often involves using specialized processes and PCB materials that can increase the overall cost. On the other hand, full spec production can achieve economies of scale, resulting in lower per-unit costs.

-

Design Revisions: PCB prototyping offers greater flexibility and easier design revisions. With this method, modifications can be made swiftly and effortlessly, without disrupting the entire manufacturing process. In contrast, implementing design changes in full-scale production can pose challenges and incur higher expenses, as they often demands adjustments to manufacturing processes and tools.

-

Quality Control: PCB prototyping typically follows a less rigorous quality control compared to full spec production. The emphasis during prototyping is on validating the design's functionality and performance, rather than adhering to precise manufacturing specifications. However, in full spec production, stringent quality control measures are enforced to guarantee that all boards meet the necessary specifications and industry standards.

Needless to say, PCB prototyping and full spec production differ in terms of quantity, cost, lead time, design revisions, and quality control. PCB prototyping is ideal for small-scale testing and validation, while full spec production is suited for large-volume manufacturing. Having said this, both these stages play significant roles in the overall PCB manufacturing process, contributing to successful and reliable electronics production. If you want to gain a thorough understanding of the differences between PCB prototyping and full spec production, it is highly recommended to get in touch with leading PCB manufacturing firms like Twisted Traces. With their expertise and knowledge in the field, they can provide you with the necessary information and guidance to make informed decisions for your PCB projects.