The Top 7 Benefits of Using Copper Clad Laminate in Electronic Circuitry

The Top 7 Benefits of Using Copper Clad Laminate in Electronic Circuitry

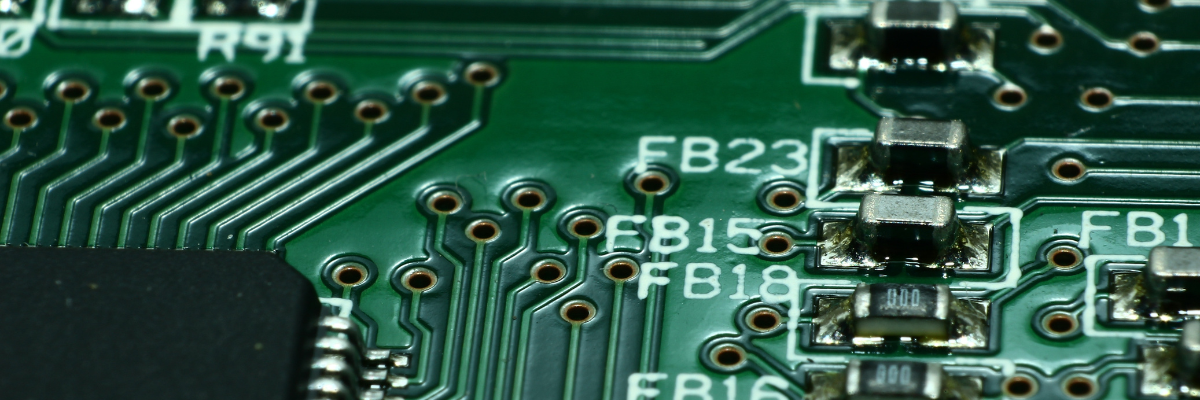

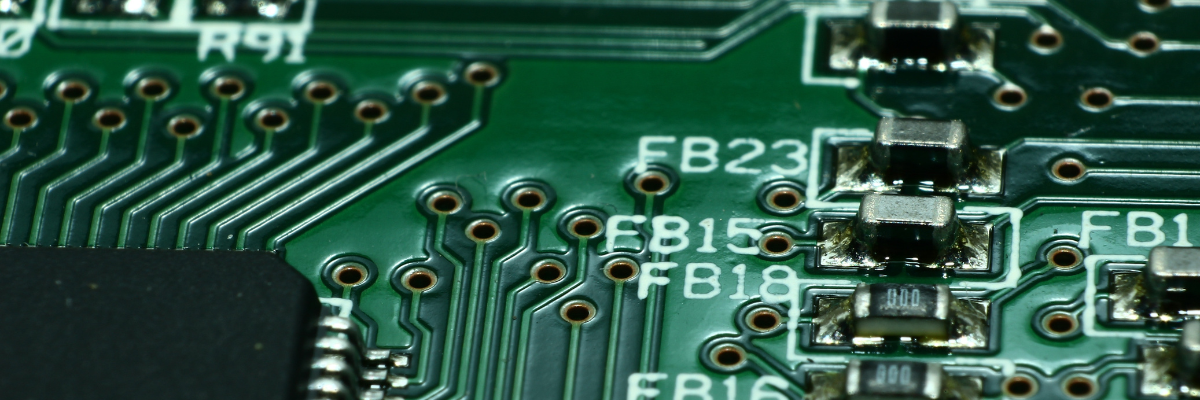

Copper Clad Laminate (CCL) is a widely used and highly preferred material in the manufacturing of printed circuit boards (PCBs). It forms the foundation upon which the electronic components are mounted. The copper layer allows for the creation of conductive paths that enable the transfer of electrical signals between different components on the board. There are different types of CCLs available in the market and the choice of CCL depends on the complexity of the PCB design and the specific requirements of the electronic circuit. There are several reasons why CCL is one of the top choices for PCBs, and this post will discuss the benefits of using CCL compared to other materials.

Why Should you Choose Copper Clad Laminate in PCB Making?

There are several reasons why you should consider choosing CCL for your PCB projects. A few of them include;

-

One key benefit of CCL is its exceptional electrical conductivity. The copper layer within the laminate promotes the efficient transmission of electrical signals, resulting in optimal functionality of electronic devices. The use of CCL also contributes to reduced risk of signal loss or distortion. This is extremely important for ensuring the smooth operation of various electronic components on a PCB.

-

Secondly, CCL offers exceptional thermal conductivity. Heat dissipation is one of the vital factors in electronic devices, as excessive heat buildup can result in malfunctions or even damage. Copper, being a highly conductive material, effectively dissipates heat, reducing the chances of thermal issues in PCBs.

-

Copper Clad Laminate offers the added benefit of exceptional durability and mechanical strength. The presence of a copper layer serves as a solid base, significantly improving the overall resilience and resistance to bending or fracturing of the PCB structure. This is especially important in industries like automotive or aerospace, where the boards are subjected to significant mechanical stress.

-

Furthermore, CCL is known for its exceptional chemical resistance. It can withstand exposure to several chemicals commonly used in electronic manufacturing processes. This includes soldering fluxes or cleaning agents. This chemical resistance ensures the longevity of the PCB and maintains its electrical performance over time.

-

Copper Clad Laminate is extremely versatile and can be seamlessly integrated into a wide range of manufacturing processes. Its ease of etching and drilling enables the creation of intricate circuit patterns, catering to the needs of single-sided as well as multi-layer PCB designs. It can also be readily laminated with other materials, such as prepreg and copper foils, during the manufacturing process, enabling the creation of multilayer PCBs with complex designs and functionalities. The ease of manufacturing with CCL enables cost-effective production and efficient assembly of electronic devices.

-

CCL is also known for its exceptional dimensional stability. This means that it can maintain its shape and dimensions even under varying temperature and humidity changes. This level of stability is extremely important for PCBs as it ensures their structural integrity and allows for precise component placement.

-

Copper clad laminate is a readily accessible material in the market. PCB manufacturers can easily source CCL, ensuring a consistent supply for production requirements. The accessibility of CCL also plays a role in its cost-effectiveness, as it eliminates the need for specialized or difficult-to-find materials.

Overall, Copper Clad Laminate’s high thermal conductivity, excellent electrical insulation, and mechanical strength make them an ideal choice for creating durable and reliable PCBs. Manufacturers like Twisted Traces have extensive experience and expertise in utilizing CCLs, hence can offer valuable insights on specific advantages of these materials. To gain a deeper understanding of the benefits associated with these laminates and their suitability for your PCB projects, reach out to experts at Twisted Traces.

.png)

.png)