Through-Hole Assembly – Component Types and Applications Explained

Through-Hole Assembly – Component Types and Applications Explained

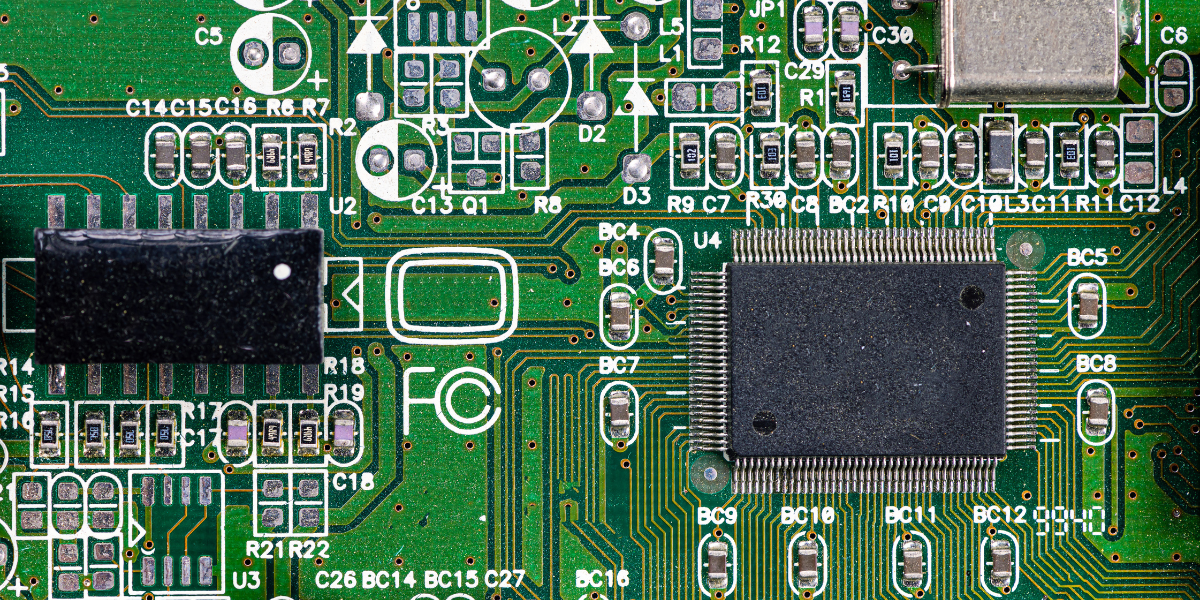

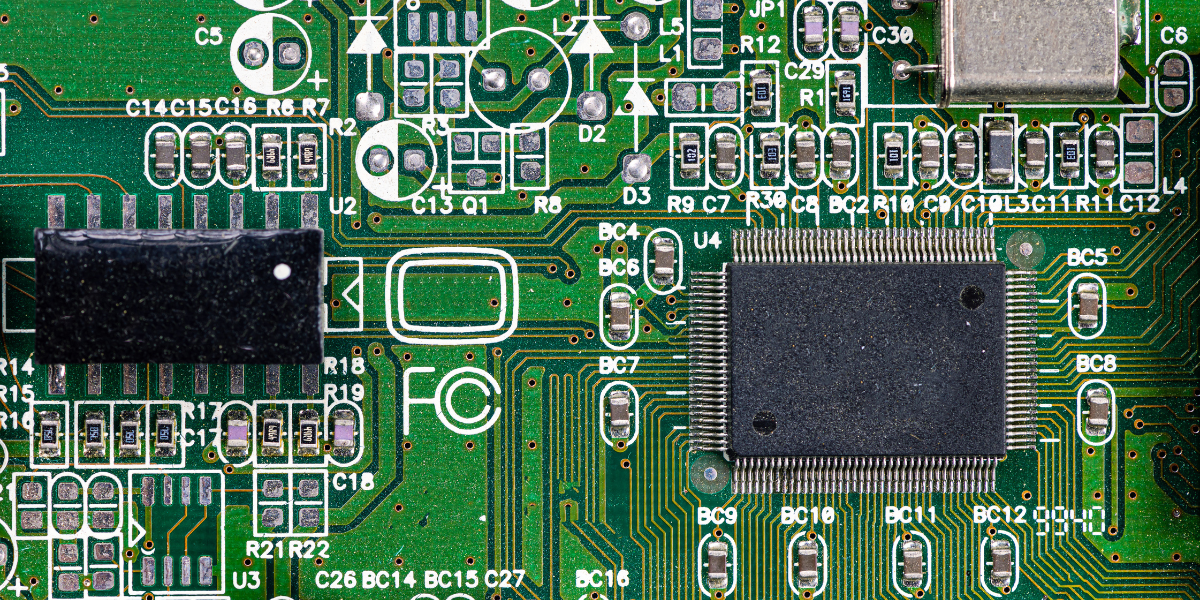

Printed circuit boards have several components mounted on them, and this is done by drilling holes of specific dimensions for components, wires, and vias. Two commonly used techniques for this process are through-hole assembly and surface mounting. Through-hole assembly is a technique used in printed circuit board (PCB) design where electronic components are mounted by inserting their leads through drilled holes in the PCB and soldered to the opposite side of the board. While surface-mount technology (SMT) has become increasingly popular in recent years, through-hole assembly remains relevant in many applications. Are you intrigued to know more about through-hole assembly? Read the post below. This post focuses on the types of components used in through hole technology and some of the most popular applications of through-hole assembly in PCB design.

Types of Through-Hole Components

As discussed, in through-hole assembly, leaded components are inserted through drilled holes in a printed circuit board. There are two main types of through-hole components. They are as follows:

-

Axial Leaded Components: Axial leaded components have leads protruding from both ends of the component along the same axis. This makes them ideal for applications where a component needs to be mounted in a line. Axial leaded components are typically cylindrical in shape, including carbon resistors, electrolytic capacitors, light emitting diodes, and so on. In a through-hole assembly, axial leaded components are mainly used for a compact fit.

-

Radial Leaded Components: These components have leads that extend from the sides of the component and are arranged in a radial pattern around the component. These components are useful for applications where they need to be mounted in a circular pattern. Radial leaded components are ideally used for high-density boards. These components include inductors, ceramic disk capacitors, and so on.

Important Applications of Through Hole Assembly

-

High Power Applications: High power applications like aerospace and military work with equipment that requires high current flow. Through-hole technique allows larger lead sizes that can accommodate thicker wires, and therefore, they are ideal for high-power applications that require more current to flow through the board.

-

High Frequency Applications: Through-hole components offer better electrical properties than their SMT counterparts. They are suitable for high-frequency applications, such as RF circuits and filters, where signal integrity and low noise are critical.

-

Harsh Industrial Applications: Through-hole components are more rugged and mechanically robust than SMT components. Their robust features make them ideal for industrial applications that require components to withstand harsh environments, including high temperatures, vibrations, shock, and so on.

-

PCB Prototyping: Through-hole components are ideal for prototyping because they are easy to work with and can be easily replaced. They are also readily available and are often cheaper than SMT components which makes them a cost-effective solution for low-volume production runs.

-

Legacy Designs: Many older electronic devices and systems are made using through-hole components. For legacy designs, if these electronic devices require repair or replacement of components, through-hole technology may be the ideal choice.

Through-hole assembly plays a great role in PCB applications, particularly in high-power, high-frequency, and industrial applications. If you are an OEM and looking to invest in PCB assemblies for your product, you may want to consider through-hole technology for component mounting. However, ensure you must partner with a trusted and reliable manufacturer who can understand your requirements and offer you the best solutions. Twisted Traces is one of the leading players in printed circuit board manufacturing and assembling. They have an experienced and skilled working team who can offer you the best solutions for your industrial applications. In addition, Twisted Traces offers high-quality PCB services you can rely on. Get in touch with the team at Twisted Traces today for further details.

.png)

.png)