The PCB industry has witnessed several changes over the years and one such was the transition from rigid to flexible circuit boards. For several years, engineers used to create flex circuit boards by connecting multiple small rigid boards with cables. This is because flex circuit board fabrication was a tedious process and quite expensive, too. However, today, they have become much common and are found in everything from wearable technology devices to smart devices, and many more. What makes these flex PCBs popular over rigid boards? Will rigid boards become a rarity in the PCB industry? Read this post to know the answers.

Although the prices of flex circuit boards have reduced over the years, they may slightly cost you more than rigid boards. In spite of this, these boards are finding applications in several electronic appliances. The following factors have contributed to their growth:

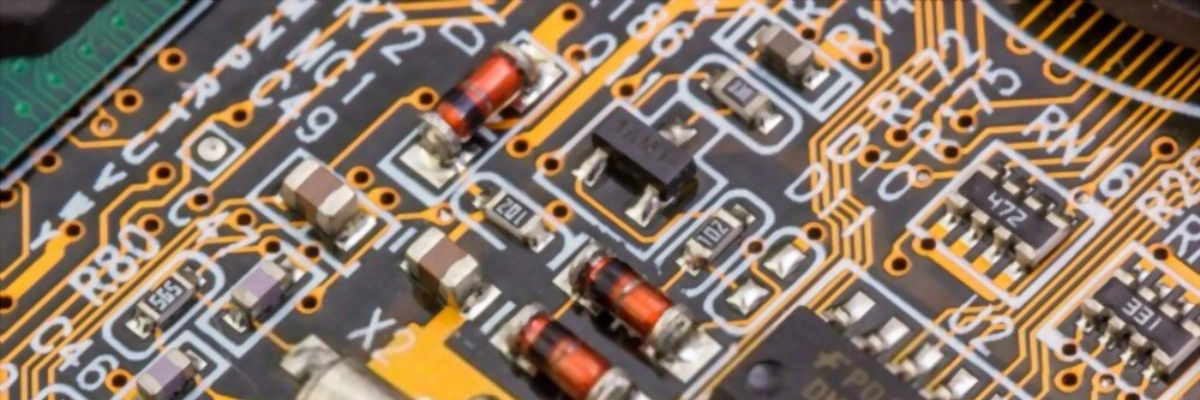

Rigid circuit boards have been for more than 50 years and were the first type of circuit boards. These circuit boards are inflexible, thus the name. They can be manufactured in single-sided, double-sided and multilayer configurations. The following are some factors that keep them going in spite of the increasing demand for flex circuit boards.

Although flex and rigid-flex circuit boards are gaining traction, rigid boards are still required in many industries. Owing to their price factors and ease of manufacturing, these boards may never wipe from the industry.

Are you planning to incorporate flex circuit boards or rigid boards in your next project? Have you been trying to fetch quotes for flex circuit boards from different PCB assembly services? If that sounds yes then you must always partner with an experienced manufacturer. Many times you may come across a huge price difference in quotes across manufacturers, however, they may follow the same techniques. Why so? In many cases, high-priced manufacturers or assembly services may not be equipped to take up the production of flex circuit boards, as they may be catering to rigid circuit board requirements. To expand their services, they may partner with third-party sources to get the work done. This will further escalate the prices and timelines. To avoid this, check if the manufacturer is experienced and well-equipped to carry the prototype to full volume production of flex PCBs. Twisted Traces is a leading player in the PCB industry delivering cost-effective and performance-driven flex, rigid-flex, and flex circuit boards for several years now. All manufacturing and assembly is performed at the company’s well-equipped facility in Illinois. The company specializes in standard and RoHS-compliant PCBs. You can get in touch with the team today to discuss your requirements.